ELIMA – Environmental Life Cycle Information Management and Acquisition for Consumer products

Description of the Project

Consumers demand reliable, efficient products in order to maintain their quality of life; these must be provided with minimum environmental impact over the whole life cycle.

The underlying problem is the lack of a closed information loop in the lifetime of a product. Information available at one stage (for example materials content known in manufacture) is lost and has to be regained at another stage (e.g. at end-of-life). As a result, high economic costs fall on producers and others in the supply chain, and high environmental costs fall on society as a whole.

As a result, industry needs systems that can integrate information about products from all stages of the life cycle. This information can then be used to manage the product life cycle, to reduce costs and to improve the design of future products. Manufacturers need to track their products in manufacture, distribution, use and at end-of-life. ELIMA systems can meet this need.

ELIMA is a project designed to test the feasibility of advanced concepts in managing the life cycle of products.

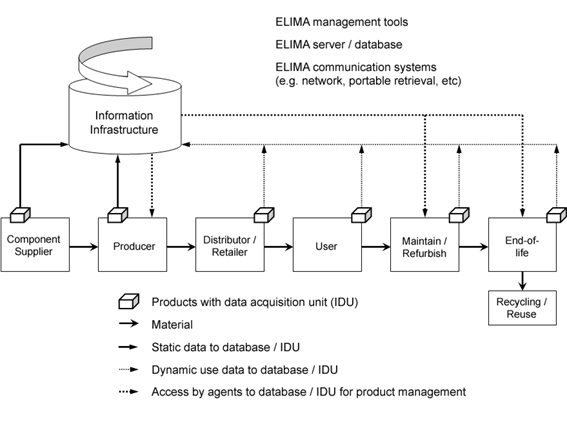

Figure 2: Flow of goods and information in an ELIMA system

The principle behind ELIMA is that the manufacturer of a product should, in taking extended producer responsibility, have data available on all stages of the product life cycle (Figure 2). This calls for an integrated information system, with databases and management tools under the control of the manufacturer, but open to access by other parties such as those involved in supply of components, the maintenance and the recycling of the product. It is this information system that the project will prototype for two typical cases. The rapidly changing nature of information technologies means that ELIMA systems must be robust and flexible; if well designed it can exploit emerging technologies to bring the manufacture, component supplier, user and recycler together as a unit.

What kind of system would be necessary to provide such a service? The ELIMA system combines so called static environmental data programmed in at the manufacturing stage e.g. materials used, together with dynamic data acquired from sensors active throughout the life cycle of the product. Therefore, future consumer product systems will need memory for data storage and systems that record data to monitor environmental parameters such as time, temperature, shock or vibration. All in all such a system should ensure a suitable data input for recycling, reuse and repair activities. Moreover, it could avoid expensive product diagnostics.

The data must be communicated to the relevant stakeholder for action; all actors in the supply chain must share data. This presents a major information processing challenge; any solution needs to be provided at extremely low cost and with low environmental impact.

Background

ELIMA is a particularly timely project given the recent EU-wide adoption of the Waste Electrical and Electronic Equipment directive (WEEE) as well as the current development of Community integrated product policy (IPP). As member states implement the WEEE directive, recovery of end-of-life products must be economic and end-of-life processing efficient. ELIMA contributes to these aims and helps meeting the objective of the directive by highlighting opportunities for reducing waste.

Scope of work

The main technical objectives of the work are:

- to design ELIMA information systems and prove their operation with two application tests,

- to develop exemplar consumer products with data provision for ELIMA,

- to produce specifications and standards, including design guidelines, reference architecture and associated product/service life cycle management tools,

- to develop and validate life cycle models for the assessment of cost and environmental benefits of product life cycle management activities,

- to evaluate the economic and environmental benefits of the ELIMA concept and to investigate consumer attitudes to the new products and services.

The ELIMA project aims to work at a European level to create high-quality jobs in manufacturing, IT and services, to reduce the environmental impact of the consumer products sector and to improve the quality of life for EU citizens.

Project Coordinator

General Domestic Appliances Ltd (UK)

Partners

Sony (DE, ES), Motorola (DE), ReUse (AT), Cybernetix (FR), Sheffield Hallam University (UK), De Montfort University (UK), SAT (AT).