Strategic CARE project

Motivation

In Europe is now a clear societal need for take-back and recycling of electronic products. “Closing the loop” would serve several (partly interlinked) goals, such as:

- Reduction of the amount of materials and environmentally relevant substances going to landfill,

- Control of environmentally relevant substances (inorganic) or annihilation of such substances (organic),

- Recycling of components and materials so that they keep maximum value, contributing to a sustainability.

Since July 1999 SCARE is in the implementation phase and it will run until June 2004. The Austrian Society for Systems Engineering and Automation is the co-ordinator of SCARE, with total project costs of 100 million EURO.

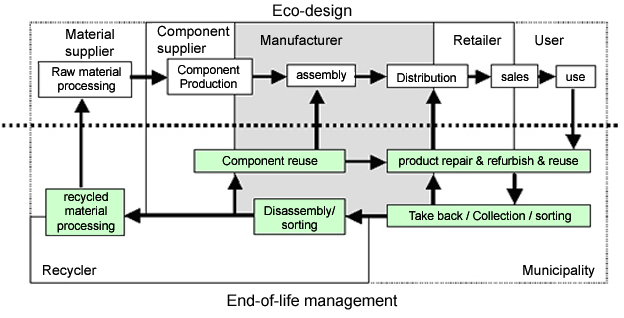

The closed product life cycle will consist of two main streams:

- The “traditional” product life chain (such as production, distribution and use) introducing environmental concerns in this stream is called “Eco-design”,

- Re-using and recycling products, components and materials (such as take back, re-use and recycling) – operation of this stream is called “End-of life Management”.

In order to successfully achieve the targets set out in the WEEE Directive, all involved parties have to act according to a common strategy to make it beneficial from both environmental, political, social and economical perspectives. Uncoordinated approaches to R&D and recycling strategies will lead to duplicated effort, misallocated investment and inefficient use of resources. A strategic approach involving and co-ordinating all actors in the product life cycle has a greater chance not only to meet legislative targets relating to collection, recycling, re-use, but to demonstrate practical ways of going beyond these targets:

- Energy consumption strategies relating to production and use stages of electronic products would contribute to a European wide strategy for reducing emissions of greenhouse gases and going beyond the 15 nations pact of an 8% reduction in next 10-14 years (Kyoto protocol),

- The involvement of many different parties requires broad co-ordination to initiate break-through steps. Endless loop-discussions have to be avoided,

- SMEs and supply-companies need to be well prepared for the resulting demands placed on them by large companies,

- Europe has good expertise in eco-design and end-of life management, particularly in the electronics sector. This should be supported to maintain Europe as a competitive strength versus US and Japan, which are now starting to catch-up,

- The “new” activities in the product life-cycle loop will catalyse employment and contribute to a sustainable social development.

Core Competencies

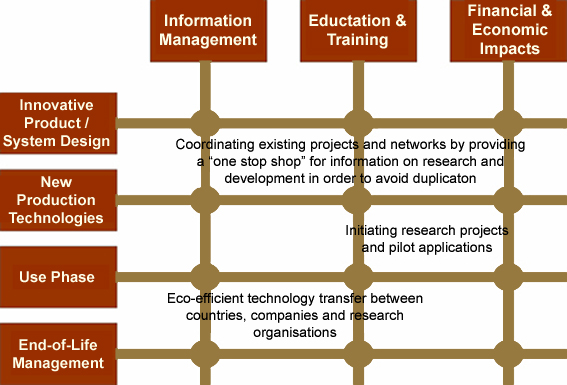

In order to explore Ecodesign and End-of-Life management the following main issues shall be considered during further investigations:

Innovative Product/System Design

- Development of products which are fast to disassemble, enabling the re-use of components and materials

- Technical innovations to reduce the environmental impact of production and product:

- Avoidance of hazardous substances

- Reduced material weight

- Lower power consumption

- Conversion of products into services (dematerialization)

- Development of new cores technologies such as solar power, grow-again materials, ...

New Production Technologies

- Investigation of specific application possibilities of materials, which have already been developed in co-operation with the suppliers

- Development of industrial, environmentally sound production processes

- Development of processes that enable the use of industrial second raw materials in manufacturing

Use Phase (Consumer Behaviour)

- Models for product performance under different use scenarios (public, corporate)

- Optimising take back and bring back systems specific to consumer groups

- Minimising energy consumption and maximising product lifetime

- Support systems for consumer organisations and government

End-of-life Management

- Product re-use (refurbishment, second hand markets, legal and guarantee issues)

- Product Take-back (collections scenarios, sorting, logistics)

- Separation (disassembly technology and separation processes, component sorting, material identification)

- Component re-use (quality assessment, second hand market, legal and guarantee issues)

- Recycled material processing (process technology, economies of scal)

In addition, there are three horizontal core competencies, which fulfil a support function for all these main issues.

Information Management

- Information exchange between all involved players in the chain

- Logistics of product, component and material handling

- Life Cycle Analysis

- Development of an in the product integrated identification unit that enables the collection of data relevant to its subsequent re-use/recycling

- Supply Chain Management

- Re-use market

Education and Training of Strategy Makers, Designers, Recyclers, ...

- Specialist education/training

- Modules within mainstream educational/training

Financial & Economical aspects

- Life Cycle costing

- eco-efficiency

- monitoring legal developments